Emakethe yanamuhla yokupakisha encintisana kakhulu, amabhokisi ephepha abe yisisombululo esithandwayo kuzo zonke izimboni. Ubungane bawo nemvelo, ukuthengeka kwawo, kanye nekhono lokwenza ngokwezifiso kuwenza afaneleke kakhulu kukho konke kusukela ekupakisheni kokudla kanye nezimonyo kuya kumabhokisi e-elekthronikhi kanye nezipho zobukhazikhazi.

Kodwa wake wazibuza ukuthi ibhokisi lephepha lenziwa kanjani ngempela efektri? Lesi sihloko sizokuhambisa yonke inqubo yokukhiqiza—isinyathelo ngesinyathelo—kusukela ekukhetheni izinto kuya ekulethweni kokugcina, sembula ukunemba kanye nobuciko ngemuva kwebhokisi ngalinye.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 1: Ukukhetha Izinto Ezifanele Zephepha

Isisekelo sanoma yiliphi ibhokisi lephepha elisezingeni eliphezulu sisezintweni zalo zokusetshenziswa. Kuye ngenhloso, isisindo, kanye nezidingo zokubukeka, abakhiqizi bavame ukukhetha kusuka ku:

Iphepha lobuciko– Iqinile futhi ihlala isikhathi eside, ilungele ukuthunyelwa kanye nokupakishwa kokuthutha.

Iphepha elimboziwe noma eliphrintiwe (isb. iphepha lobuciko)– Ubuso obubushelelezi kanye nombala okhanyayo, ofanele amabhokisi ezipho aphezulu.

Ikhadibhodi elinothayela– Ukumelana okuhle kakhulu nokuchotshozwa, okusetshenziselwa kakhulu ukuthutha.

Phakathi nalesi sigaba, ifektri ihlola usayizi womkhiqizo, isisindo, kanye nokusetshenziswa okuhlosiwe ukuze income impahla nobukhulu obuhle kakhulu—ithole ibhalansi efanele phakathi kokuqina, izindleko, kanye nokukhanga okubonakalayo.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 2: Umklamo Wesakhiwo Owenziwe Ngokwezifiso

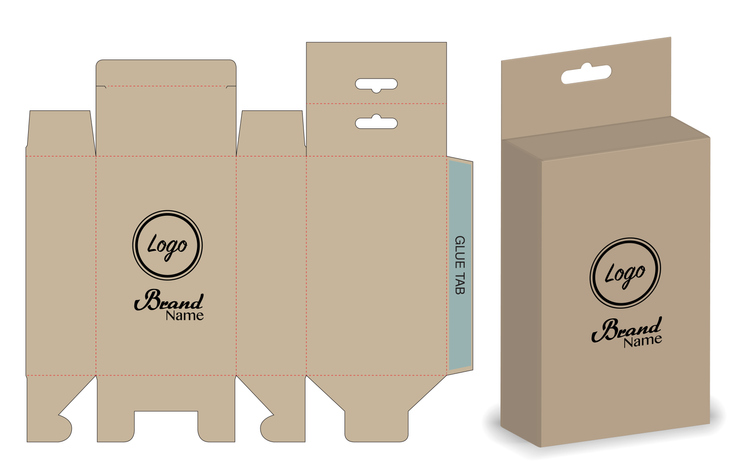

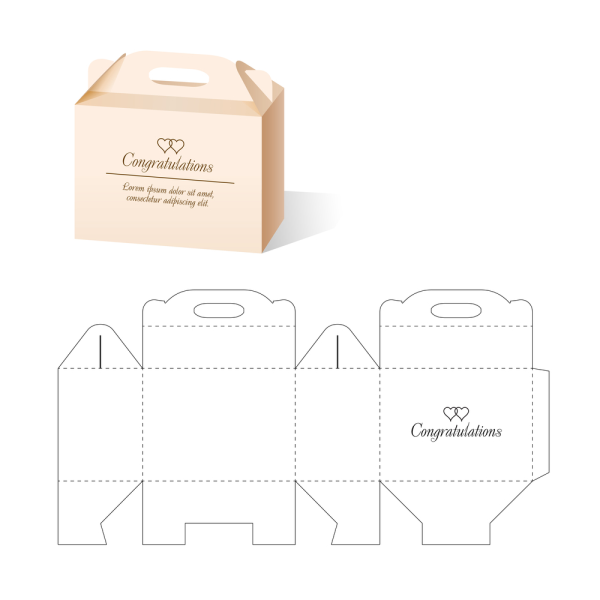

Amabhokisi ephepha awafanelani nosayizi owodwa. Onjiniyela bezakhiwo baklama usayizi webhokisi, ukuma, kanye nesitayela sokuvula ukuze lifane kahle nomkhiqizo. Lesi sigaba sibalulekile kokubili ekusebenzeni nasekubukeni.

Besebenzisa isofthiwe ye-CAD ethuthukisiwe, abaklami bakha amamodeli e-3D kanye nezakhiwo ezisikiwe ngodayi, belingisa indlela ibhokisi elizogoqa, libambe, futhi livikele ngayo okuqukethwe kwalo. Kumabhokisi anobukhazikhazi noma anomumo ongajwayelekile—njengezivalo zikagesi noma amabhokisi esipho afana nesitayela sedrowa—ukusampula kwesibonelo kuvame ukwenziwa ngaphambi kokuba kuqale ukukhiqizwa ngobuningi.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 3: Ukuphrinta Okusezingeni Eliphezulu

Uma ukufaka uphawu kanye nezithombe kubalulekile (okuyinto evame ukuba yiyo), ibhokisi lingena esigabeni sokuphrinta. Kuye ngomklamo, isabelomali, kanye nomthamo, amafektri angasebenzisa:

Ukuphrinta kwe-offset– Ukuphrinta okunesinqumo esiphezulu, okunemibala egcwele okufanelekela ukugijima okukhulu.

Ukuphrinta kwe-UV– Imibala egqamile enokuphela okuphakanyisiwe noma okucwebezelayo, evame ukusetshenziselwa ukupakisha okuphambili.

Ukuphrinta kwesikrini sesilika noma i-flexo– Iwusizo ezindaweni ezithile noma ekubunjweni.

Ukulawulwa kwekhwalithi okuqinile kuqinisekisa ukukhiqizwa kombala okunembile kanye nokucaca kwesithombe okubukhali. Ibhokisi lephepha eliphrintiwe kahle liba yimpahla enamandla yokubeka uphawu kanye nethuluzi lokumaketha.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 4: Ukusika Ngokudayisela Ukuze Ube Nokunemba

Ngemva kokuphrinta, amashidi ayasuswaukusika ngodayizibe yizimo ezithile kusetshenziswa izikhunta ezenziwe ngokwezifiso. Lesi sigaba sakha yonke imigqa egoqekayo, amathebhu, namaphaneli adingekayo ukwakha isakhiwo sebhokisi.

Izimboni zesimanje zisebenzisa imishini yokusika ngokuzenzakalelayo eqinisekisa ukunemba okuphezulu kanye nokushintsha okusheshayo. Ukusika okuhlanzekile kanye nokugoba okunembile kubalulekile ukuqinisekisa ukugoqa okubushelelezi kanye nekhwalithi yebhokisi ehambisanayo.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 5: Ukugoqa Nokunamathisela

Okulandelayo, amashidi asikiwe ngodayi aya entanjeni yokugoqa nokunamathisela. Izisebenzi noma imishini ezenzakalelayogoqa ibhokisi ngemigqa ebekwe amaphuzu kusengaphambilibese usebenzisa izinamathiseli ezinobungani nemvelo ukuze uhlanganise amaphaneli ndawonye.

Lesi sinyathelo sinikeza ibhokisi isimo salo sokuqala. Ngemiklamo eyinkimbinkimbi kakhulu njengamabhokisi esipho agoqekayo noma amabhokisi aqinile anezifakelo, ukuhlanganiswa okuyingxenye ngesandla kungadingeka ukuqinisekisa ukunemba nokuqeda.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 6: Ukwakha Nokucindezela Ibhokisi

Ukuqinisekisa ubuqotho besakhiwo kanye nokubukeka kobungcweti, amabhokisi avame ukudlulaukwakha ukucindezelaLe nqubo isebenzisa ukushisa nokucindezela ukuqinisa imiphetho, ukucaba izindawo, nokulungisa isimo unomphela.

Ukuze uthole ukupakishwa okuphezulu, lesi yisinyathelo esibalulekile esithuthukisa umuzwa wokuthinta kanye nemiphetho ebukhali, okwenza ibhokisi libukeke licwebezelisiwe futhi lisezingeni eliphezulu.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 7: Ukuhlolwa Kwekhwalithi

Ibhokisi ngalinye eliqediwe lidlula ekuhlolweni kokulawula ikhwalithi okunzima, okuvame ukufaka:

Ukuhlola amaphutha okuphrinta, imihuzuko, noma ukungcola

Ukulinganisa ubukhulu kanye nokubekezelelana

Ukuqinisekisa amandla okubopha iglue kanye nesakhiwo sayo sonke

Ukuqinisekisa ukuvumelana kombala kanye nokuqeda

Amabhokisi adlula kuzo zonke izivivinyo zekhwalithi kuphela avunyelwe ukupakishwa nokulethwa. Lokhu kuqinisekisa ukuthi yonke into ethunyelwe ihlangabezana nezindinganiso eziphakeme zomkhiqizo.

Hukuze wenze ibhokisi le-3D ngephepha:

Isinyathelo 8: Ukupakisha Nokulethwa Kokugcina

Uma sekuvunyelwe, amabhokisi ayapakishwa acwebezelisiwe noma ahlanganiswe ndawonye, kuye ngezidingo zamakhasimende. Bese efakwa emabhokisini, afakwe emaphethini, bese efakwa ilebula ukuze athunyelwe.

Ifektri iqinisekisa ukupakishwa okuvikelayo kanye nokuphathwa kahle kwempahla ukuze kugcinwe amabhokisi esesimweni esihle ngesikhathi sokuthutha. Ukulethwa ngesikhathi nangokuphepha kuyingxenye ebalulekile yokunikezwa kwenkonzo ephelele, ikakhulukazi ekuthunyelweni kwamanye amazwe.

Hukuze wenze ibhokisi le-3D ngephepha:

Isiphetho: Ibhokisi Lingaphezu Kokupakishwa Nje

Kusukela ezintweni zokwakha kuya emshinini kuya kubasebenzi, ibhokisi ngalinye lephepha limelela ukuvumelana komklamo, ubunjiniyela, kanye nokulawulwa kwekhwalithi. Kwamabhizinisi, ibhokisi elenziwe kahle aligcini nje ngokuvikela—liphakamisa umkhiqizo futhi liqinisa isithombe somkhiqizo emehlweni abathengi.

Kungakhathaliseki ukuthi udinga amabhokisi e-kraft anobungani nemvelo noma ukupakisha izipho okuphrintiwe okunobukhazikhazi, ukusebenzisana nefektri yokupakisha enolwazi kuqinisekisa ukuthi uthola ikhambi elenzelwe wena—kusukela emqondweni kuya ekulethweni.

Ufuna umenzi wokupakisha onokwethenjelwa?

Sinikeza izixazululo zebhokisi lephepha ezenzelwe wena ngokugcwele ezifanela izidingo zakho zomkhakha, umkhiqizo, kanye nophawu. Xhumana nathi ukuze uthole ukubonisana kwamahhala noma ucele isampula namuhla!

Isikhathi sokuthunyelwe: Meyi-29-2025