How to create gift boxes: From Factory to Creativity, Making Packaging a Part of Value

In modern consumption, gift boxes are no longer just the role of outer packaging; they have become a medium for brand expression and emotional transmission. For professional factories that produce gift boxes, how to make “packaging” move from practicality to creativity is the key to determining market competitiveness. This article will take a production perspective to introduce the entire process of gift box creation, from material selection, design style to production processes, and explore how to perfectly combine creativity with quality.

How to create gift boxes?Material Preparation: Laying the Foundation for Quality and Creativity

From the factory’s perspective, the first step in creating a gift box is the scientific selection of materials. High-quality raw materials not only determine the appearance and texture of the gift box but also affect production efficiency and environmental performance.

1. Box Material Selection

In gift box production, the most commonly used materials include:

Finished box body materials: Paper boxes (such as gray board, white card paper), plastic boxes, wooden boxes, etc. Paper gift boxes are the most common, with advantages such as low cost, good printing performance, and recyclability; plastic and wood are often used for high-end gift packaging.

Self-made box structure: For customized orders, the factory will, according to customer requirements, use thick cardboard or composite cardboard, and through processes such as die-cutting, embossing, and gluing, form it by itself. This can achieve higher dimensional accuracy and design flexibility.

2. Decoration and Accessories

Decorative materials are the key to giving the gift box “vitality”. Commonly used include:

Ribbons, strings, ropes: used for carrying or decoration;

Labels, embossed tags: enhancing brand recognition;

Decorative paper, dried flowers, small accessories: adding detail beauty.

Modern factories often enhance process precision through automatic labeling machines, laser engraving, etc., making the decoration both beautiful and durable.

3. Filling and Inner Linings

The inner lining not only protects the gift but is also an important part of the aesthetic display.

Common fillers: colored paper chips, foam particles, EVA inner lining, etc.;

High-end solutions: using flocking fabric, silk padding, custom mold inner lining, making the gift box more upscale.

How to create gift boxes?Design Style: Converting Market Demand into Creative Expression

Design is the soul of the gift box. For production factories, design not only needs to pursue beauty but also needs to take into account cost and the feasibility of mass production.

1. Theme Design

Different application scenarios determine the style direction of the gift box.

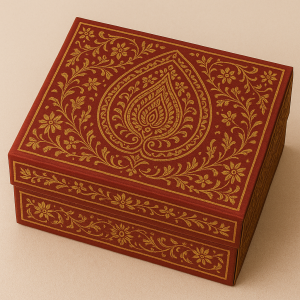

Holiday gift boxes: such as Christmas, Spring Festival, Mother’s Day, etc., with festive colors such as red, gold, and green, and adding holiday pattern elements;

Brand customization: enterprise customers pay more attention to logo printing, color uniformity, and LOGO position, to reflect brand recognition;

Personalized customization: based on the recipient or special occasions for exclusive design, highlighting uniqueness and emotional warmth.

2. Color and Texture Combination

During production, the factory will provide various process combinations based on customer plans, such as:

Contrasting color combination: using contrasting colors to enhance visual recognition;

Coordinated color scheme: creating a unified visual experience;

Surface treatment processes: coating, embossing, embossing, UV gloss, etc., which not only enhance the texture but also increase waterproof and wear resistance.

Through the combination of color and process, the gift box is not only a packaging but also becomes an extension of the brand image.

How to create gift boxes? Production Steps: The Precise Process from Creativity to Finished Product

In the gift box factory, every step is related to quality. Precise process flow is the key to turning the design drawing into reality.

1. Mold and Cutting

Based on the design drawing, use CNC die-cutting machines or knife molds for precise cutting.

The cutting error is controlled within ±0.5mm, ensuring that the assembled box body fits tightly.

2. Assembly and Gluing

Use fully automatic box-filling machines or manual gluing to assemble each component. For complex structures or high-end customized boxes, often use manual assistance assembly to ensure fine craftsmanship.

3. Surface Decoration and Quality Inspection The final step is the finishing process, such as stringing, applique, and gold stamping.

Before leaving the factory, each batch of gift boxes must undergo appearance inspection, size inspection, and load-bearing test to ensure safety during transportation and use.

How to create gift boxes?Notes: Quality, Safety and Environmental Protection are Equally Important

1. Safety and Health

All materials used must comply with environmental standards (such as ROHS, REACH certifications), be non-toxic and odorless, especially for food gift boxes or children’s products.

2. Practical Design

Before production, the factory conducts load-bearing tests and stacking tests to ensure the stability of the box and prevent deformation or cracking during transportation.

3. Environmental Concept

With the rise of the green packaging trend, more and more factories are beginning to adopt recycled paper materials, water-based ink printing, and degradable glue to achieve an environmental closed-loop from production to recycling.

How to create gift boxes? Additional Creativity: Making Gift Boxes More Valuable for Business

For gift box manufacturers, creativity is not only about the appearance design, but also an embodiment of “added value”.

1. Interaction and Experience Design

Nowadays, packaging is not just “packing”, but also “transmitting”.

Some gift boxes will be designed with hidden card areas, small drawers, or QR code labels. Users can scan them to view brand stories or customized blessings, achieving interactive experience.

2. Multi-Use and Extensibility

High-end gift boxes often have secondary utilization value – they can be used as storage boxes, jewelry boxes, or home decorations.

This “continuation of use” concept not only enhances brand favorability but also aligns with the trend of environmentally friendly consumption.

How to create gift boxes?Conclusion: The Value Upgrade of Gift Boxes from Manufacturing to Creation

From the perspective of the gift box production factory, the birth of every package is a combination of art and technology.

From the selection of raw materials to the realization of creativity, from the precision of machines to the warmth of manual work, every step reflects the spirit of craftsmanship.

The true creation of gift boxes is not only the external beauty, but also the internal quality and emotional transmission.

When packaging becomes the extension of the brand and the carrier of expressing feelings, it is no longer just a “box”, but a warm workpiece.

Key Words:#Gift Box Creation#Gift Box Design#Gift Box Factory#Gift Box Packaging Production#Creative Packaging Design# Customized Gift Box#Gift Box Production Process# Eco-friendly Gift Box#Gift Box Customization Factory#Brand Gift Packaging

Post time: Oct-28-2025