In today’s highly competitive packaging market, paper boxes have become a preferred solution across industries. Their eco-friendliness, affordability, and customization potential make them ideal for everything from food packaging and cosmetics to electronics and luxury gift boxes.

But have you ever wondered how a paper box is actually made in a factory? This article will walk you through the entire manufacturing process—step by step—from material selection to final delivery, revealing the precision and craftsmanship behind every box.

How to make a 3d box out of paper:

Step 1: Choosing the Right Paper Material

The foundation of any quality paper box lies in its raw material. Depending on the purpose, weight, and appearance requirements, manufacturers typically select from:

Kraft paper – Strong and durable, ideal for shipping and transport packaging.

Coated or printed paper (e.g., art paper) – Smooth surface and vivid color output, perfect for premium gift boxes.

Corrugated cardboard – Excellent cushioning and crush resistance, widely used for logistics.

During this stage, the factory evaluates the product’s size, weight, and intended application to recommend the best material and thickness—striking the right balance between durability, cost, and visual appeal.

How to make a 3d box out of paper:

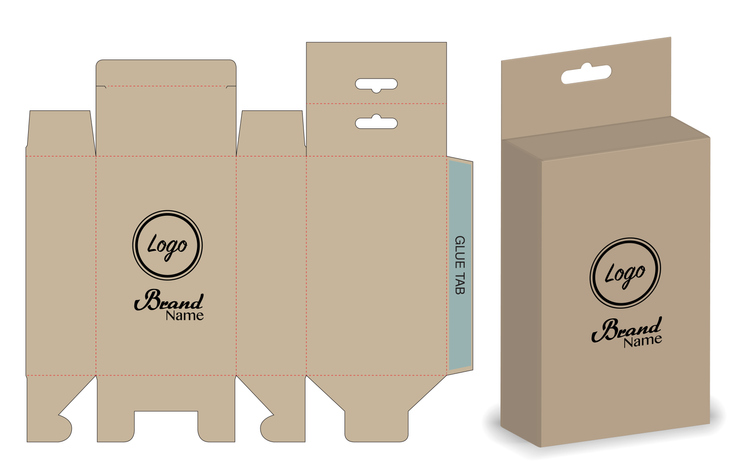

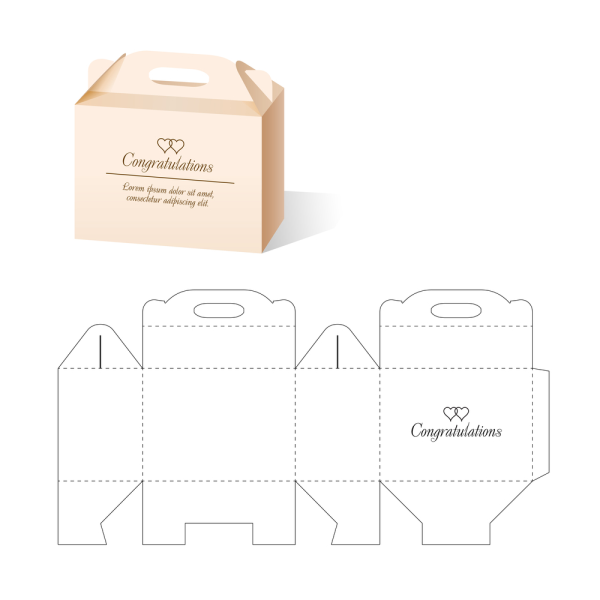

Step 2: Custom Structure Design

Paper boxes aren’t one-size-fits-all. Structural engineers design the box’s size, shape, and opening style to match the product perfectly. This phase is crucial for both functionality and aesthetics.

Using advanced CAD software, designers create 3D models and die-cut layouts, simulating how the box will fold, hold, and protect its contents. For luxury or irregular-shaped boxes—like magnetic lids or drawer-style gift boxes—prototype sampling is often conducted before mass production begins.

How to make a 3d box out of paper:

Step 3: High-Quality Printing

If branding and visuals are essential (which they often are), the box enters the printing phase. Depending on the design, budget, and volume, factories may use:

Offset printing – High-resolution, full-color printing suitable for large runs.

UV printing – Vibrant colors with a raised or glossy finish, often used for luxury packaging.

Silk screen or flexo printing – Useful for specific surfaces or textures.

Strict quality control ensures accurate color reproduction and sharp image clarity. A well-printed paper box becomes a powerful branding asset and marketing tool.

How to make a 3d box out of paper:

Step 4: Die-Cutting for Precision

After printing, sheets are die-cut into specific shapes using custom-made molds. This stage creates all the folding lines, tabs, and panels needed to form the box’s structure.

Modern factories use automatic die-cutting machines that ensure high precision and fast turnaround. Clean cuts and accurate creases are critical to ensure smooth folding and consistent box quality.

How to make a 3d box out of paper:

Step 5: Folding and Gluing

Next, the die-cut sheets move to the folding and gluing line. Workers or automated machines fold the box along pre-scored lines and apply eco-friendly adhesives to join the panels together.

This step gives the box its initial form. For more complex designs like collapsible gift boxes or rigid boxes with inserts, partial manual assembly may be required to guarantee precision and finish.

How to make a 3d box out of paper:

Step 6: Box Forming and Pressing

To ensure structural integrity and professional appearance, boxes often undergo press-forming. This process uses heat and pressure to reinforce edges, flatten surfaces, and fix the shape permanently.

For high-end packaging, this is a vital step that enhances the tactile feel and sharp edges, making the box look polished and premium.

How to make a 3d box out of paper:

Step 7: Quality Inspection

Each finished box goes through a rigorous quality control check, which typically includes:

Checking for print defects, scratches, or smudges

Measuring dimensions and tolerances

Verifying glue bonding strength and overall structure

Ensuring consistency in color and finish

Only boxes that pass all quality checks are approved for packaging and delivery. This guarantees that every piece shipped meets the brand’s high standards.

How to make a 3d box out of paper:

Step 8: Final Packing and Delivery

Once approved, the boxes are packed flat or assembled, depending on customer requirements. They’re then boxed, palletized, and labeled for shipment.

The factory ensures protective packaging and efficient logistics to keep the boxes in perfect condition during transit. Timely and safe delivery is a critical part of the full-service offering, especially for international shipments.

How to make a 3d box out of paper:

Conclusion: A Box Is More Than Just Packaging

From material to machine to manpower, every paper box represents a harmony of design, engineering, and quality control. For businesses, a well-made box doesn’t just protect—it elevates the product and reinforces the brand image in the eyes of consumers.

Whether you need eco-friendly kraft boxes or luxurious printed gift packaging, partnering with an experienced packaging factory ensures you get a tailor-made solution—from concept to delivery.

Looking for a reliable packaging manufacturer?

We offer fully customized paper box solutions tailored to your industry, product, and branding needs. Contact us for a free consultation or request a sample today!

Post time: May-29-2025