How to Make a Cardboard Box: Full Process Analysis of Industrial-grade Customized Production

Introduction

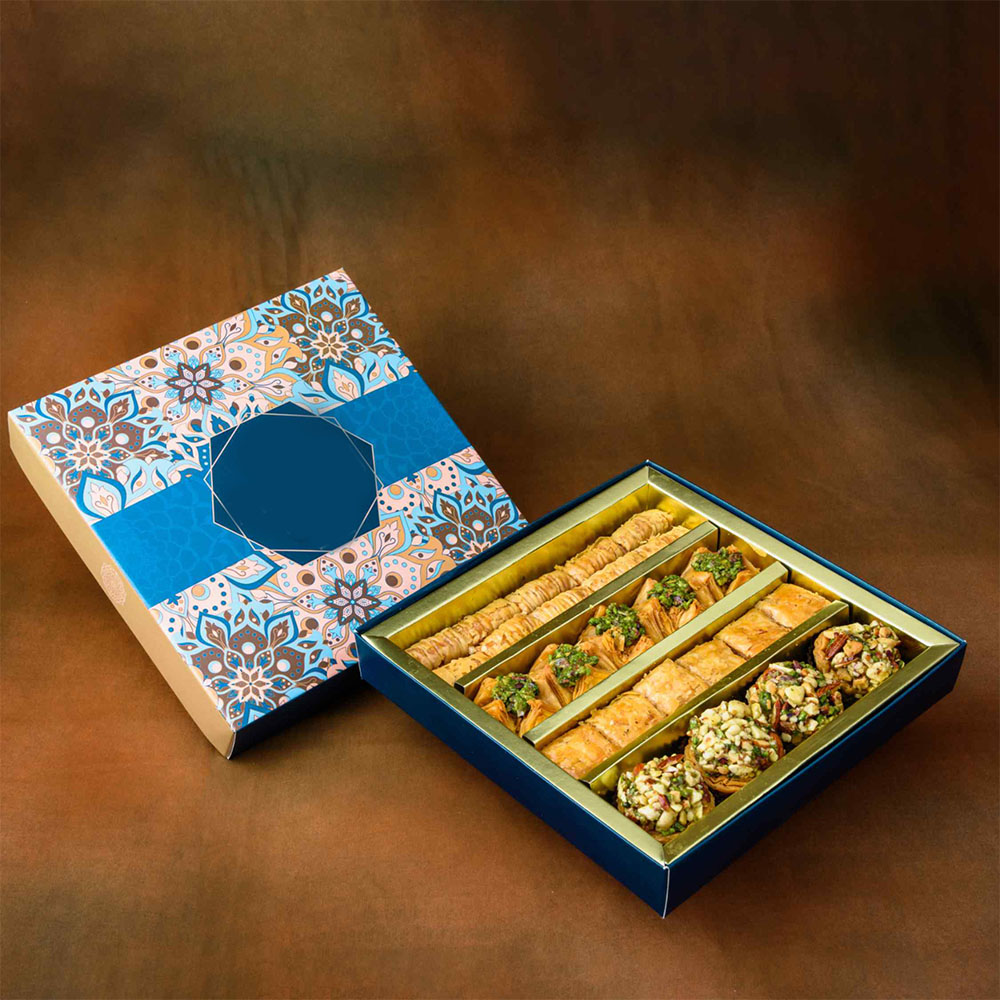

In the modern packaging industry, Cardboard boxes have become the main choice for packaging various commodities. Whether it is food, cosmetics or daily necessities, a paper box with a stable structure and exquisite printing is not only an important carrier for protecting the products, but also a core display carrier for the brand image.

When many people search for “how to make a cardboard box“, they often only see DIY tutorials. But for enterprises, what can truly enhance the value of products is the industrial-grade bulk customized production process. This article is provided by Dongguan Fuliter Paper packaging Co.,LTD (specializing in customized food packaging boxes for 15 years), which comprehensively interprets the entire process from design, printing to finished product delivery for you.

I. How to make a cardboard box-Material selection stage: The first step in determining quality

1. Selection of base paper and structure

The first step in the production of industrial paper boxes is to select the appropriate paper material. Common types include:

Gray-backed white board paper: Affordable price, suitable for ordinary packaging;

White card paper (C1S/C2S) : Fine texture, suitable for high-end food and gift packaging;

Corrugated Board (Corrugated board) : used for transport or structural packaging;

Kraft paper: It has high strength and good pressure resistance, and is often used for outer packaging boxes.

The thickness (0.3-5mm) and weight (250-500g/m²) of cardboard directly affect its load-bearing capacity and stiffness. Food packaging needs to take into account moisture resistance, oil resistance and environmental protection certifications (such as FDA or FSC) additionally.

2. Environmental protection and food safety standards

Food packaging must use food-grade cardboard and ink. During the production process, Fuliter uses non-toxic water-based inks and environmentally friendly adhesives, which comply with the EU ROHS and US FDA food contact safety requirements, ensuring that the products are hygienic and odorless.

Ii. How to make a cardboard box-Structural Design and Prototyping Stage: From concept to substance

1. Structural and development drawing design

The designer will draw the Die Cut Layout based on the product size, usage scenarios and loading methods.

Common box types include:

Tuck End Box

Socket type (Auto-Lock Bottom

Drawer type (Drawer Box

Folding Carton

After completing the size calculation in the CAD design software, the designer will provide the client with a 3D structural effect drawing to help preview the opening and closing methods and space utilization.

2. Sampling and confirmation

Before formal production, physical samples will be made using a Sample Cutter or a laser sample-making machine:

Check whether the dimensions, structure and sealing are accurate.

Confirm the folding line and die-cutting position;

Evaluate the printing color, lamination effect and hand feel.

Only after the customer confirms that the sample is correct will it enter the mass production stage. This step is extremely crucial for avoiding later losses and rework.

Iii. How to make a cardboard box-Printing Stage: The core link of brand visuals

1. Selection of printing method

According to the order quantity and effect requirements, you can choose:

Offset Printing: The most commonly used, suitable for high-precision color printing;

Flexo Printing: Low cost, suitable for transporting outer boxes;

Digital Printing: Suitable for small-batch or multi-version production.

Fuliter uses Heidelberg four-color offset printing machines, ensuring precise color reproduction and supporting Pantone spot color matching.

2. Prepress preparation and color management

Before printing, the following steps need to be taken:

Confirmation of plate making, plate assembly and proofing;

Check the dot density, bleed line and color saturation;

Use the ICC color management system to ensure consistency in batch printing.

3. Ink and Lamination

It is recommended to use water-based ink or UV ink for food packaging. The following processes can be carried out after printing:

Lamination (matte film/glossy film) : Enhances moisture resistance and abrasion resistance;

Gilding/embossing/partial UV: Enhance visual layers and brand texture.

Iv. How to make a cardboard box-Die-cutting and creasing: Determine the forming accuracy

After the printing is completed, the cardboard enters the die-cutting process.

Cut according to the shape of the unfolded drawing using a precision Die Cutter;

Complete the Creasing process simultaneously to make the subsequent folding smoother.

Check whether the depth of the die and the position of the indentation have shifted.

The Fuliter factory adopts fully automatic die-cutting equipment, which can complete cutting, creasing and waste removal in one go, improving efficiency and precision.

V. How to make a cardboard box-Bonding and Assembly: Make the structure more stable

1. Box gluing process

The cardboard is die-cut and then enters the Folder Gluer.

The machine automatically applies glue, folds and presses.

Use environmentally friendly water-based glue for rapid curing;

For thick paper or special box types, hot melt adhesive or mechanical lockstitch structures can be adopted.

2. Manual auxiliary processes

For some complex structures (such as drawer boxes and top and bottom cover boxes), it is still necessary to manually stick the inner lining or outer cover to ensure the fineness of the details.

3. Forming and folding

Some box types (such as folding flat boxes) will be folded and stored in the warehouse at the end, allowing customers to quickly unfold and shape them when using them.

Vi. How to make a cardboard box-Quality Inspection and Packaging for Shipment: Ensure that each box is qualified

1. Quality inspection process

Fuliter has multiple testing standards:

Visual inspection: Printing alignment, color difference, lamination flatness;

Dimensional measurement: The error is controlled within ±1mm;

Structural tests: Folding flexibility, load-bearing capacity, sealing strength;

Food safety testing: Random sampling is used to test ink migration and odor residue.

2. Finished product packaging and shipment

Qualified products will be packed into boxes and labeled with batch labels for traceability. For export orders, moisture-proof paper and pallet packaging are used to ensure transportation safety.

Vii. How to make a cardboard box-Sustainability and Brand Value Extension

Modern packaging not only pursues functionality but also attaches great importance to environmental protection and brand image. Fuliter fully adopts in production:

Fsc-certified eco-friendly paper materials;

Degradable lamination technology;

Green ink and pollution-free glue.

In addition, customized box shapes not only enhance packaging efficiency but also strengthen brand memory points. By printing logos, brand slogans or exclusive color schemes, paper boxes are upgraded from “containers” to “brand communicators”.

Conclusion

The production of industrial-grade cardboard boxes is far more complicated than it seems on the surface. From paper selection, structural design, printing, die-cutting to quality inspection and shipment, every step is related to the quality and brand value of the final packaging.

With years of experience in food packaging and a complete equipment system, Fuliter Paper Box is capable of providing customers with one-stop services ranging from creative design, sampling to mass production.

If you are planning to create high-quality, environmentally friendly and safe paper box packaging for your brand, welcome to visit our food box series page

Learn more about customized solutions and successful cases.

Tags: #customization #paperbox #foodbox #giftbox #highquality #cardboard #chocolate #sweet #cardboard

Post time: Nov-08-2025